LNG whole point solution

LNG-- liquefied natural gas (Liquefied Natural Gas, referred to as LNG) is recognized as the most clean energy on the earth. A colorless, tasteless, non-toxic and non corrosive, its volume is about the same amount of gaseous natural gas volume 1/600, liquefied natural gas's weight is only about 45% of the same volume of water. The manufacturing process is the first gas field production of natural gas purification treatment, liquefied under ultra-low temperature, the use of liquefied natural gas ship.

LNG is currently mainly used for city taxis, buses provide liquid or gaseous fuels. Compared with CNG, LNG has higher compression ratio, more easy to transport, while the gas purity and cleanliness is better. With the need of the implementation of the national clean energy policy and energy strategic reserve, the development prospect of LNG expansive.

Classification of LNG filling station:

Fixed type LNG filling station

Mainly used in filling in the 3~5 million M fand / day, filling quantity is big case of using such a filling station,

Covers an area of 5~7 acres, mainly used for heavy-duty trucks, filling more larger volume of vehicles or large city of intercity bus. 3~5 million M fand / day, standard fueling station main equipment according to double pump double liquid machine equipment configuration.

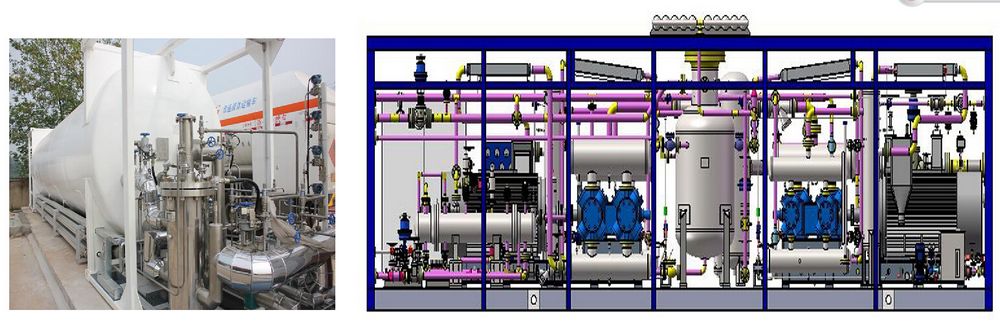

Skid mounted type LNG filling station

Flexible, less land occupation. Do not rely on natural gas pipeline network, only the LNG tanker carrying LNG as source. All process equipment in the station are mounted on a skid, small overall dimensions (length * width * height size is 12m * 2.5m * 3.31M); control system installed in a converted standard containers (size length * width * height is 6m * 2.5m * 3M); filling before LNG filling station the overall total quality is only 21.8t, very suitable for automobile transportation. Gas station location can be changed at any time according to the market demand, especially in the city proper.

Mobile LNG refueling station

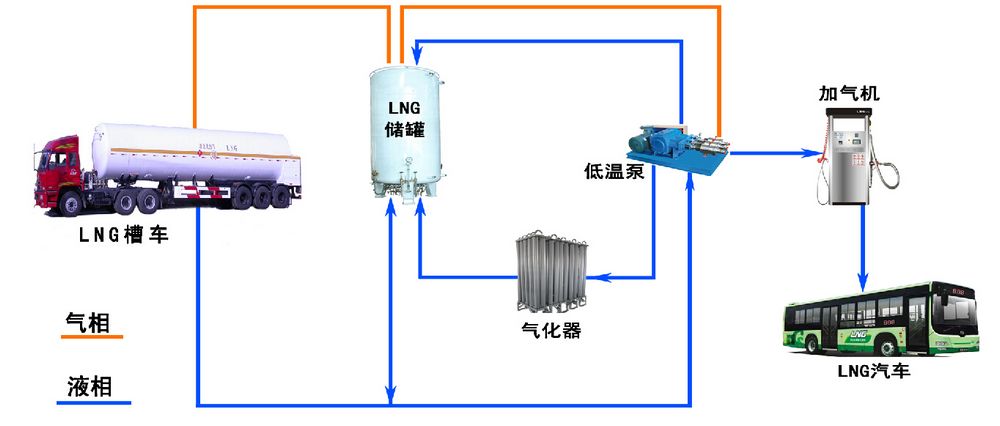

LNG filling station working flow: